About PP Flute

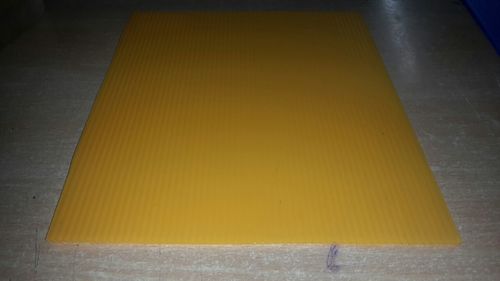

Orion Printpack is a leading manufacturer of PP Flute Board, also known as Polypropylene Fluted Sheet / PP Corrugated Sheet, designed for versatile, lightweight, and durable packaging and signage applications.

Manufactured using high-quality polypropylene polymer, Orion Printpack PP Flute Boards deliver superior strength, water resistance, and long-lasting performance for industrial, commercial, and outdoor use.

Product Description

PP Flute Boards are twin-wall, fluted polypropylene sheets that offer an excellent strength-to-weight ratio. These boards provide superior impact resistance, waterproofing, and chemical resistance, making them ideal for applications such as packaging boxes, advertising boards, returnable packaging, floor protection, partitions, and industrial storage.

Orion Printpack offers PP Flute Boards in various thicknesses, colors, and sizes to meet customized industry-specific requirements.

Specification Details

- Material 100% Virgin Polypropylene (PP)

- Thickness 2 mm 12 mm

- Standard Sizes 1220 1830 mm, 1300 2000 mm, 1500 2400 mm (Custom sizes available)

- Density / GSM Range 250 GSM 3000 GSM

- Flute Design Twin-Wall / Hollow Structure

- Color Options White, Black, Blue, Yellow, Red, Green, Grey, Custom colors

- Surface Finish Matte / Gloss / Printable

- Water Resistance 100% Waterproof

- UV Resistance Available on request

- Temperature Resistance 20C to +80C

- Printing Compatibility Screen Printing, UV Printing, Digital Printing

- Additional Options Corona Treatment, Anti-Static, Fire Retardant, Customized Die-Cut

Key Features

- Lightweight yet high-strength material

- 100% waterproof & moisture-resistant

- Chemically inert and corrosion-resistant

- Excellent impact & tear resistance

- Reusable & long-lasting

- Easy to cut, fold, punch, weld & fabricate

- Available in multiple colors & thicknesses

- Suitable for high-quality printing & branding

Advantages of Orion Printpack PP Flute Board

- Multi-purpose Applications: Suitable for packaging, signage, advertising, construction protection, and more.

- Cost-Effective Replacement: A durable alternative to cardboard, wood, and acrylic boards.

- Eco-Friendly: Recyclable and reusable, reducing packaging waste.

- Superior Weatherproofing: Performs well in outdoor conditions with UV-stabilized options.

- High Customizability: Can be produced in custom sizes, colors, and flute strengths.

- Enhanced Safety: Non-toxic, lightweight, and easy to handle.

- Durable Structure: Twin-wall design provides excellent rigidity and impact protection.

Applications

- Packaging boxes & returnable packaging

- Floor protection sheets at construction sites

- Sign boards, display boards & advertising panels

- Separator sheets, layer pads & partitions

- Agriculture and nursery beds

- Industrial storage and logistics

- File covers, folders, and craft applications

Versatility Across ApplicationsPP Flute sheets are widely used in packaging, signage, construction protection, and advertising displays due to their customizable dimensions, surface finishes, and printability. They adapt well to various functional and aesthetic requirements, ensuring optimal performance in each application. Their impact strength and flame retardant options make them dependable across different environments.

Exceptional Durability and ProtectionWith a high tensile strength above 25 MPa, these sheets resist impacts and harsh chemicals, making them suitable for demanding industrial and outdoor conditions. Available in both smooth and textured finishes, they retain their integrity between -20C to +80C, and offer complete waterproofing, prolonging the lifespan of packaging and structures.

Sustainable and Cost-Efficient Choice100% recyclability and lightweight design position PP Flute sheets as an environmentally responsible option. The sheets can be easily fabricated, printed, and reused, providing cost savings and operational flexibility for businesses. Custom sizes and colors enhance branding while supporting eco-friendly practices.

FAQs of PP Flute:

Q: How are PP Flute Hollow Corrugated Sheets fabricated for different applications?

A: The sheets are fabricated using techniques like cutting, bending, and printing, depending on the intended application. Their lightweight and rigid nature makes them easy to handle, allowing seamless customization of size, shape, and surface finish to suit packaging, signage, and construction needs.

Q: What benefits does the 100% waterproof feature of PP Flute sheets offer?

A: Being completely waterproof, PP Flute sheets protect contents and structures from moisture, humidity, and exposure to liquids. This feature is particularly advantageous for packaging products, outdoor signage, and construction protection in challenging environments.

Q: When should UV-stabilized PP Flute sheets be requested?

A: UV-stabilized sheets are recommended when the product will be exposed to prolonged sunlight or outdoor conditions. Requesting UV stabilization enhances longevity and prevents degradation, making these sheets suitable for external signage and protective applications.

Q: Where can PP Flute sheets be used in commercial or industrial settings?

A: PP Flute sheets are widely used across India in industries like packaging, advertising, construction, and logistics. Their customizable size and surface finish make them suitable for protective barriers, printed displays, and formwork liners in manufacturing, retail, and service sectors.

Q: What is the process for customizing the sheet size, color, or surface finish?

A: To customize PP Flute sheets, clients can specify their preferences for size, color, and surface finish when ordering. Manufacturers adjust dimensions up to 1220 x 2440 mm or larger, and offer color options such as blue, white, yellow, and grey, as well as smooth or textured surfaces to match unique requirements.

Q: How does the excellent chemical resistance of PP Flute sheets enhance their usage?

A: The superior resistance to acids, alkalis, and oils ensures that PP Flute sheets remain unaffected in tough chemical environments. This property makes them ideal for packaging chemicals, protective applications in laboratories, and construction sites where exposure to corrosive substances is frequent.